Interview with CEO & Founder Sonja Djønne on the Heymat’s sustainability initiatives.

With the vision of offering Scandinavian design floor mats in the high quality of industrial floor mats the couple Sonja Djønne and Thoralf Lian founded the Heymat label in 2015, based in Mo i Rana, Norway. For the founding couple, environmentally friendly and sustainable production is a matter of course right from the start, with a focus on the recycled materials used, high durability and premium quality – factors that are closely interlinked and influence each other:

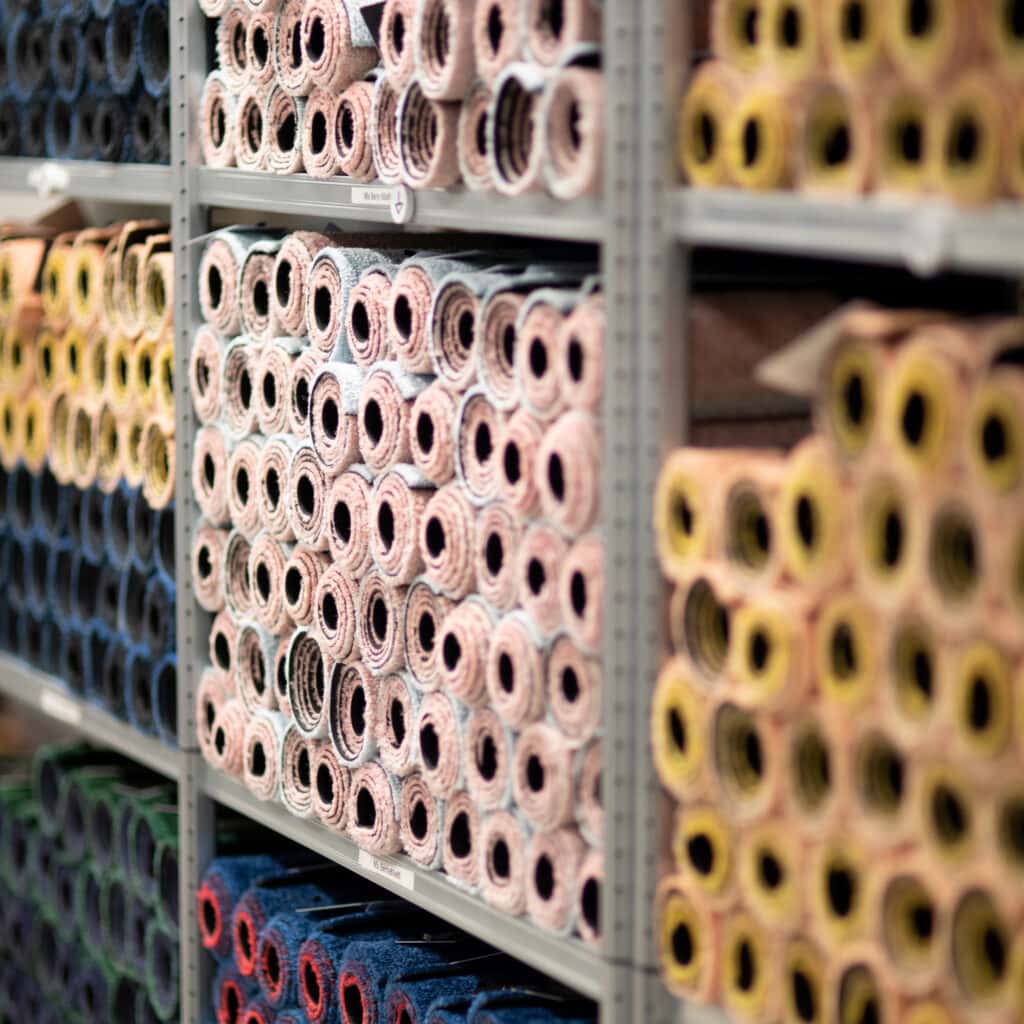

Recycled materials

Only nitrile rubber is used for the back of the mats, which consists of around 30 percent recycled rubber waste. In 2017, Heymat replaced nylon for the production of the pile with the hard-wearing and quick-drying material PET. Since the end of 2020, the pile of 90 percent of the mats has been made from 100 percent recycled PET plastic bottles.

Premium quality

A Heymat must last for as many years as possible, inspire and inspire. That’s why Heymat is particularly concerned with the outstanding quality of the mats – made in Europe – which in turn also contributes to a longer service life for the other floor coverings in the living area, as dirt and impurities are quickly absorbed and not carried on into other rooms.

Longevity

Heymat also takes the concept of sustainability into account when developing its timeless designs. After all, a doormat must not only last for many years, but also be visually appealing for as long as possible. The Norwegian label therefore invests a great deal of time in its design processes. The aim is to create products that will inspire for generations to come. The high premium quality guarantees a long service life, which means that Heymat can be used in the entrance area, in the kitchen, on the balcony or even as a play area in the children’s room for many years to come.

Why is the use of recycled materials so important to Heymat?

“Yarn made from recycled plastic bottles is an ideal material for doormat production because plastic textiles dry very quickly, are particularly hard-wearing and extremely durable. We are of course aware that these synthetic materials are not sustainable in the first instance. However, as our products only have such a long service life thanks to the use of high-quality plastics, we did not look for an alternative material, but considered how we could use recycled materials sensibly and make production as sustainable as possible.”

If waste products are generated during production, are they recycled?

“Just as every Heymat can be easily recycled, we also endeavor to give new life to as much waste as possible in our production. For example, all rubber waste is recycled directly on site and used for the production of new items. We have fabric and fiber waste collected by an external company, where it is recycled and processed into new material. Paper and plastic waste is disposed of separately, collected and recycled directly at the production sites and at Heymat’s Norwegian headquarters.”

What sustainability initiatives is Heymat implementing?

“We are constantly working to reduce our carbon footprint and find the most environmentally friendly solutions for all company processes. These can be small steps such as saving printer paper at our company headquarters. But it can also be through the increased use of recycled materials, which we continue to work on intensively, or through other green innovations such as the use of renewable water energy for heating, as we do in Norway. In view of the rapid pace of technological change, we are working with our partners to implement many advances in this area as quickly as possible.”

How does Heymat organize and control the supply chain? Is it tightly meshed or does it consist of many different partners?

“We believe that few, but long-term and intensive partnerships are the best choice. We are in close contact with all our partners and each of them is subject to the same ethical, social and sustainable standards that we set ourselves. Each partner is audited by us to ensure that our requirements are consistently met. For example, we have been working with the production facilities for our mats for a very long time and are constantly developing new solutions to make production even more environmentally friendly.”

How does Heymat reduce its CO2 footprint in connection with the sometimes very long delivery routes?

“Our production facilities are located in the USA and Europe, which means we can guarantee short transportation routes, which in turn has a positive effect on our carbon footprint. In the next few years, we are planning to open an additional warehouse centrally located in Europe to further reduce our carbon footprint. We generally give a lot of thought to the emissions we cause and try to reduce them as much as possible. In addition, we pursue a policy of ‘less is more’ when it comes to packaging. We use as little cardboard as possible, completely avoid plastic packaging and only provide each mat with a narrow elastic band.”

Sonja Djønne, CEO & Founder of Heymat

About Heymat

Heymat is a family business run by Sonja Djønne and Thoralf Lian from Mo i Rana, Norway, which has specialized in high-quality doormat design since 2015. The first collection was launched with great success in 2016. The various designer mats are now available in large parts of Europe, the USA and Asia. Based on function, quality, sustainability and Scandinavian design, Heymat develops high-quality products for spaces where everyone should feel welcome.

iThere are no comments

Add yours